Gaithersburg New

Roof

|

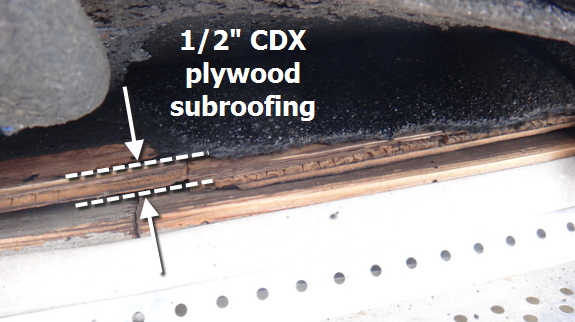

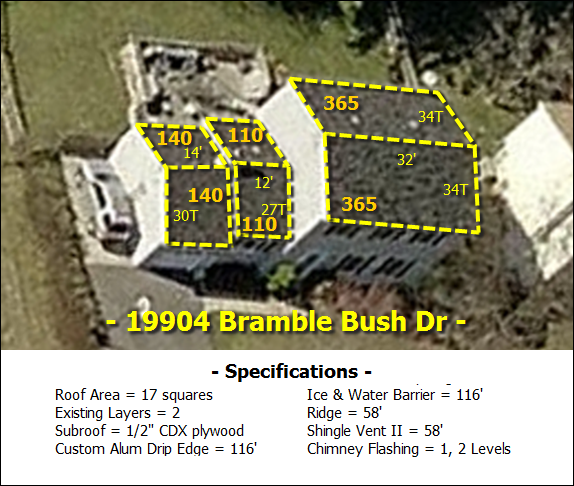

Before: The home is finally ready for a new roof ... existing shingles are 25 year "builder's shingles," 3-tab, one layer, with 1/2" plywood underlayment. Roof pitch is between 5/12 and 6/12 ... walkable. |

We will be changing to Certainteed Landmark Lifetime Architectural Shingles to upgrade the look and warranty. |

|

|

|

|

|

Since we are already tearing the entire roof and felt off, it's the perfect time to cut bigger slots in the sub-roofing and install a new Shingle Vent II ridge vent system. The added volume of air circulated throughout the attic will keep the area cooler AND drier: a. Keeping the insulation dry and

making it more effective. There will be 58' of Shingle Vent II installed on

this project. |

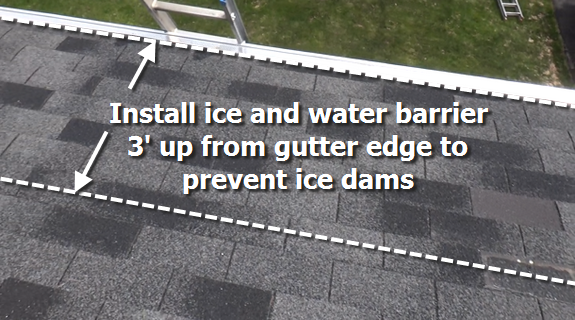

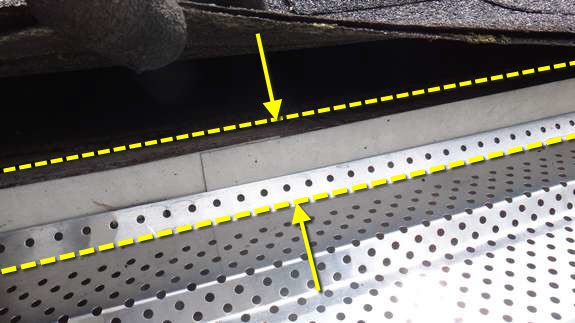

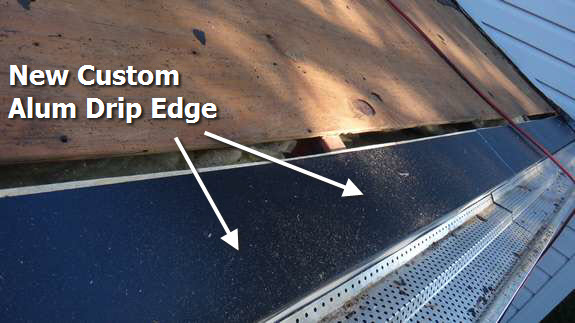

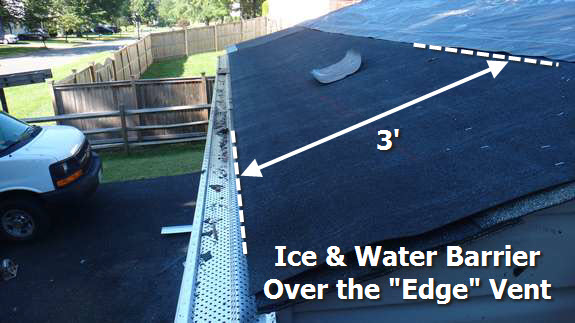

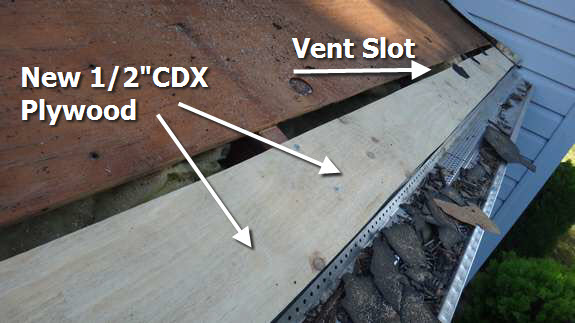

Ice and Water Shield will be added at all gutter edges, valleys, and penetrations (chimneys, etc.) to guard against ice dams and bring the existing roof "up to code." Ice and water shield permanently bonds itself to the plywood surface AND the aluminum drip edge to prevent damage to the wood sub-roof from ice dams and horizontal rain. There will be about 116', 3 feet wide, when this job is completed. Underneath the Ice and Water Shield at the eave edges will be our Custom formed aluminum drip edges that help direct water into the gutters so that the sub-roof and fascia wood is protected from water and ice dams for the life of your roof. We custom form them on site on our sheet metal brake so that they fit your roof exactly. There will be about 116' of 6" wide drip edge applied to this project. Before the roofing shingles are installed, instead of using the old fashioned "tarpaper" (that almost everybody else STILL uses), we use Berger UDL Synthetic Underlayment, which is much more effective at protecting against leaks caused by "wind driven rain" ... and has the added benefit of discouraging mold growth -- unlike tarpaper. Custom chimney

flashing. I haven't seen

anybody else do this routinely, and on this project, we'll use custom formed white

aluminum to blend with the surroundings. Chimney

"counter flashings" will be sealed using OSI QUAD (the best) siding sealant. |

|

|

|

|

During & After:  The Roof Center is delivering shingles and accessories! |

|

Now the REAL action begins, 36 squares into the dump truck ... about 9,000 lbs@ 250 lbs/square. |

|

|

|

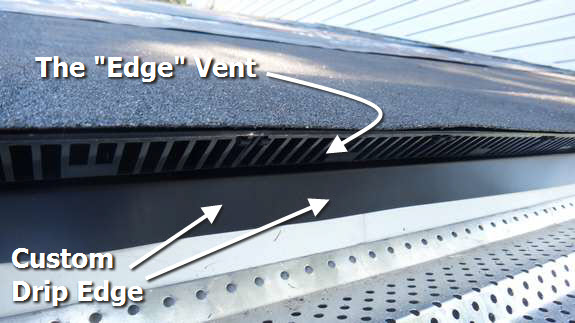

The existing gutters are hung about 2" lower than most ... we may need to raise a few strategically since we're adding 1.5" (Edge Vent) to the edge of the roof. No worries. |

|

|

Our custom 5" x 1" aluminum flashing goes down first ... |

... then the Edge Vent, covered by 3' of Ice and Water Barrier. |

|

Synthetic underlayment is the applied after the Ice and Water Barrier. |

|

|

|

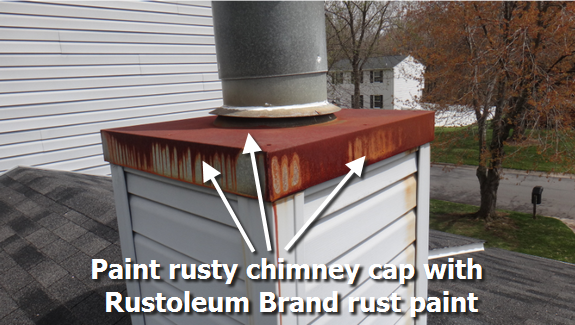

Remembering the old rusty chimney cap ... |

All flashings (including existing Attic Fan) were cleaned and painted with Rustoleum Brand rust inhibiting paint. |

New neoprene/aluminum pipe collars were installed and pipes painted as well ... |

|

Proper slots were cut in the peak and the Shingle Vent II system installed. |

|

|

|

|

|

|

|

|

Done deal! ... with the exception that we'll be raising the gutters on the two lower front eaves for aesthetics. |

|

|

%20837-7400.png)